Reading Clock Data in Mitsubishi PLC using TRD Instruction – A Simple Guide

In modern industrial automation, knowing the exact time is important. Time helps in scheduling tasks, recording events, and controlling machines based on time. Mitsubishi PLCs (Programmable Logic Controllers) come with a built-in Real-Time Clock (RTC) to help you do just that.

One easy and powerful way to read clock data in Mitsubishi PLC is by using the TRD instruction.

Contents:

- What is the TRD Instruction in Mitsubishi PLC?

- Reading Clock Data in Mitsubishi FX5U-PLC System.

- Clock Data in FX3 Series PLCs (Compatible Area).

- Practical Uses of TRD Instruction in Mitsubishi PLC.

- Why Use TRD Instruction in Mitsubishi PLC?

What is the TRD Instruction in Mitsubishi PLC?

TRD (Time Read) is a special command used in Mitsubishi PLCs to read current clock data from the CPU’s real-time clock. This includes:

- Year

- Month

- Day

- Hour

- Minute

- Second

- Day of the week

When you use the TRD instruction, the clock data is saved into SD (System Data) registers. This data can then be used in your program for time-based logic and automation.

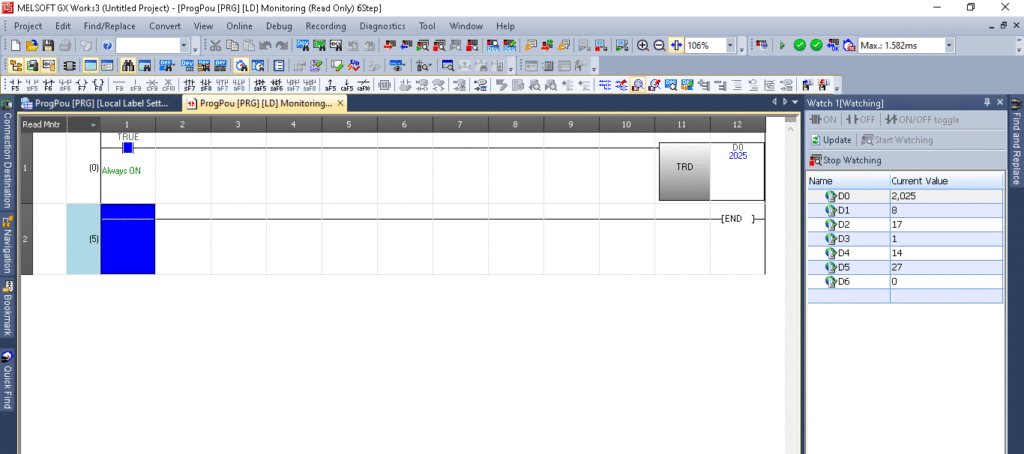

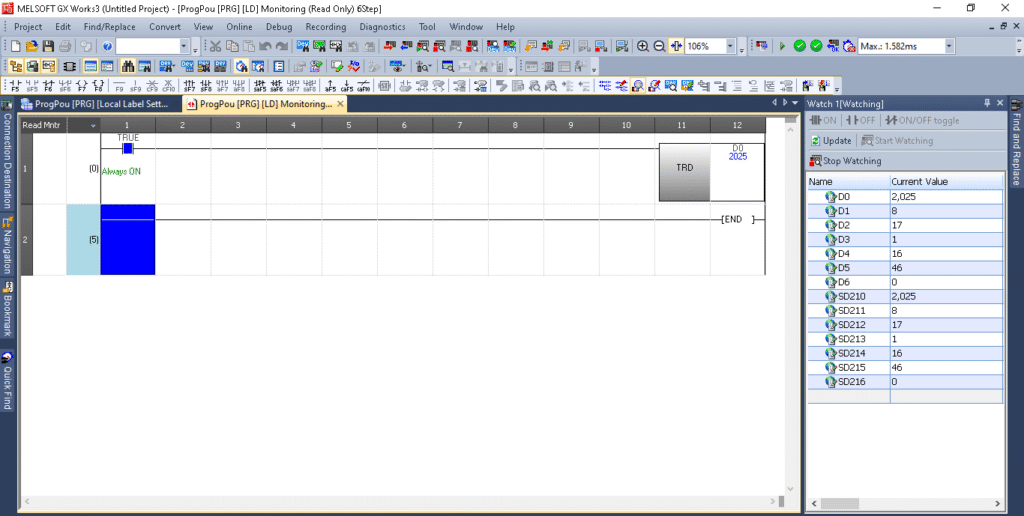

Reading Clock Data in Mitsubishi FX5U-PLC System

If you’re using the Mitsubishi FX5U-PLC System , the TRD instruction works by storing clock data into these system registers:

If you don’t want to use TRD Instruction, you can also get the Clock data from internal register.

| Register | Data Stored |

|---|---|

| SD210 | Year (e.g. 2025) |

| SD211 | Month (1–12) |

| SD212 | Day (1–31) |

| SD213 | Hour (0–23) |

| SD214 | Minute (0–59) |

| SD215 | Second (0–59) |

| SD216 | Day of the Week (0–6) |

💡 This data is in binary format and can be used to create logic based on current time or day.

Clock Data in FX3 Series PLCs (Compatible Area)

For older models like the Mitsubishi FX3 Series, clock data is stored in different registers (SD8013 to SD8019):

| Register | Data Stored |

|---|---|

| SD8013 | Second |

| SD8014 | Minute |

| SD8015 | Hour |

| SD8016 | Day |

| SD8017 | Month |

| SD8018 | Year |

| SD8019 | Day of the Week (0–6) |

This area works the same way but is designed for FX3-compatible PLCs.

Practical Uses of TRD Instruction in Mitsubishi PLC

Using the TRD instruction Mitsubishi PLC can help in many real-world automation tasks:

🔁 Time-Based Control

Start or stop machines based on time (e.g., only during work hours).

📝 Event Logging

Record when an error or event happens by saving a timestamp using clock data.

⏰ Time-Based Interrupts

Pause or delay a process at certain times.

👥 Shift Management

Control machines based on worker shifts by checking the day and time.

Why Use TRD Instruction in Mitsubishi PLC?

The TRD instruction is essential for reading clock data in Mitsubishi PLCs like the FX5U and FX3 series. It allows the PLC to understand the current time, date, and day, which helps in:

- Automating processes

- Scheduling operations

- Logging events

- Managing work shifts

Mitsubishi FX5U-PLC System for Clock-Based Automation

Use of RTC in STP Plant

1. Time-Based Pump Operation

You can schedule pumps (inlet, transfer, sludge) to run at specific times of the day. For example:

- Inlet pump ON: 6:00 AM

- Sludge pump ON: 10:00 PM

This saves energy and ensures proper treatment based on actual flow patterns.

2. Automatic Event Logging

The RTC allows the system to log events with timestamps. If a pump fails or an alarm is triggered, the exact time is recorded for future analysis.

3. Shift Management

In large STP plants, operations may change based on shifts. Using the RTC, PLCs can switch between modes or screens depending on the day or time.

Example:

- Morning shift mode: 6 AM to 2 PM

- Evening shift mode: 2 PM to 10 PM

4. Scheduled Membrane Cleaning

In MBR-based STP systems, membrane backflushing or cleaning cycles can be run automatically at midnight or during low-load hours using RTC scheduling.

5. Safety Checks & Maintenance Reminders

- Automatic maintenance alerts after set run hours or dates

- Safety shutdowns during non-operating hours

RTC in Mitsubishi PLC for STP Automation

Using Mitsubishi PLCs like the FX5U, you can easily access RTC data using the TRD instruction. The PLC can:

- Read current time from system registers (e.g., SD210 to SD216)

- Compare time to preset values

- Trigger actions like pump start, alarm logging, or shift changes

Benefits of Using RTC in STP Plant

| Benefit | How RTC Helps |

|---|---|

| Automatic Scheduling | Run motors only during needed times |

| Reduced Manual Intervention | Less need for operators |

| Energy Saving | Avoids running equipment 24/7 |

| Accurate Logging | Time-stamped logs for alarms and events |

| Improved Maintenance | Reminders and run-hour tracking |

If you want to implement time-based logic, the Mitsubishi FX5U-PLC System is a great choice. With a reliable real-time clock and TRD instruction, you can automate complex tasks with ease.

Using the TRD instruction in Mitsubishi PLC makes it easy to access real-time clock data and bring powerful time-based features to your automation projects..

Share this blog with others who are working with Mitsubishi PLCs and help them learn how to use the TRD instruction effectively!