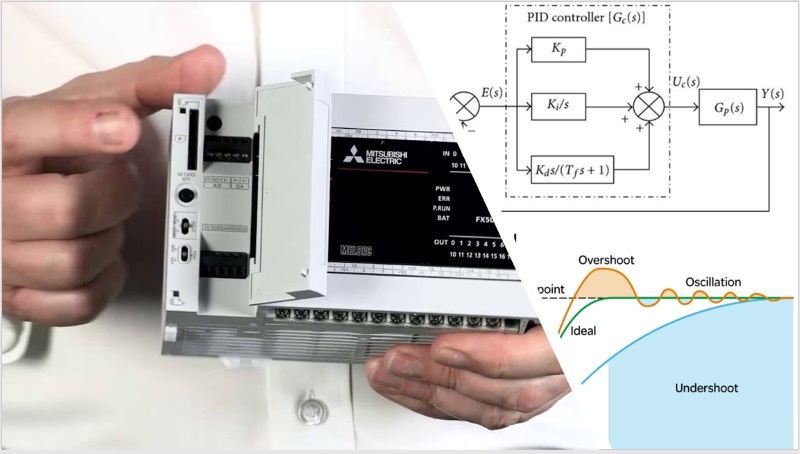

Step-by-Step: Logging Data from FX5U to SD Card

Let’s break down how to set up SD card logging on the FX5U. MELSEC FX5U data recording, 📥 Download available at the end of this article.

Step 1: Prepare Your Hardware

- Insert a compatible SD or SDHC card into the FX5U’s built-in slot.

- Format the card if necessary (FAT16/FAT32 recommended).

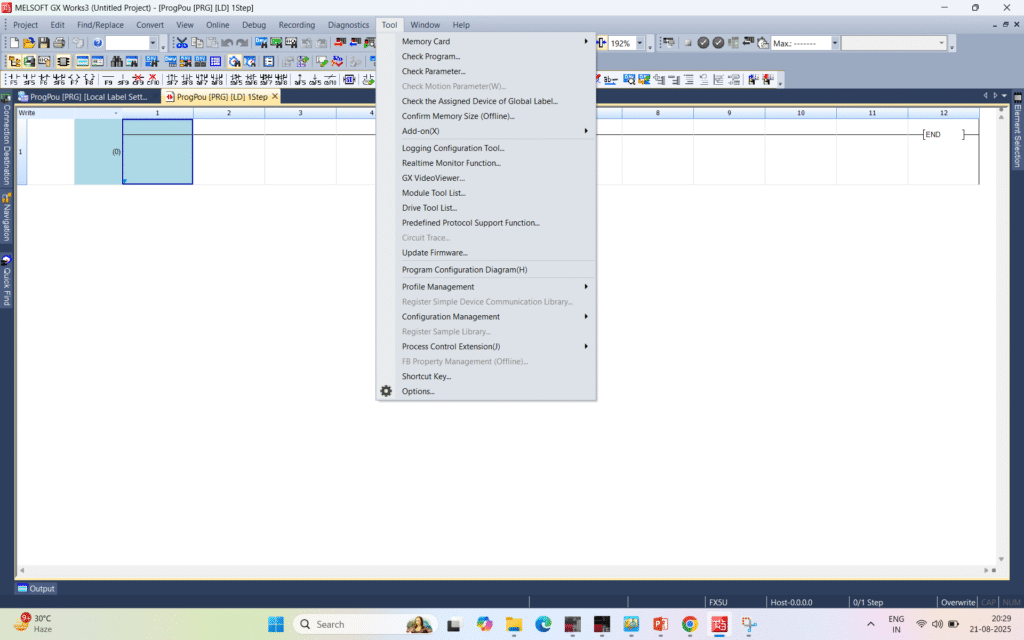

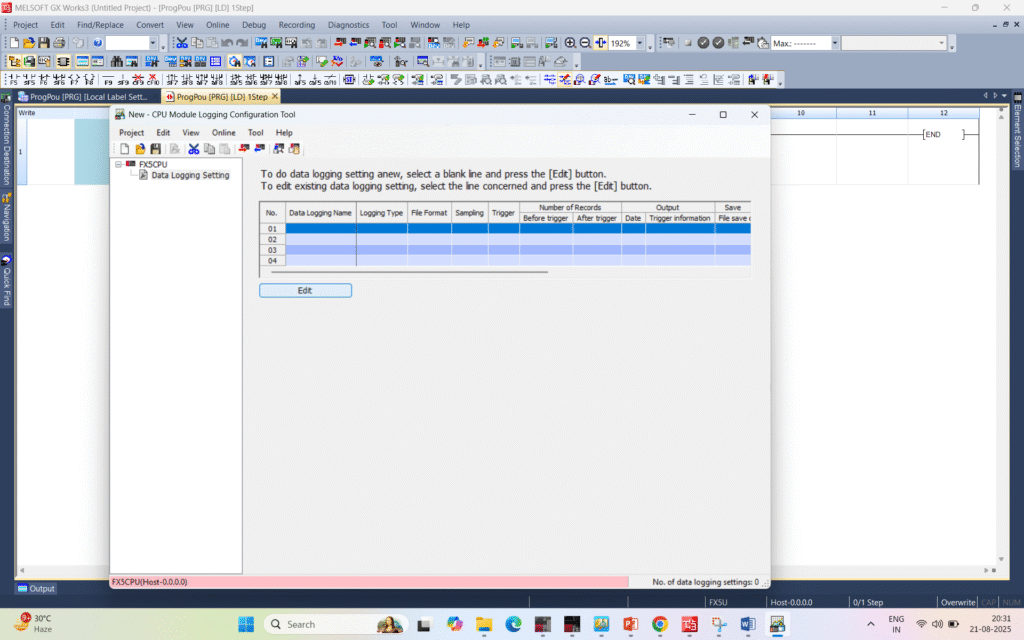

Step 2: Open Logging Settings in GX Works3

- Navigate to the “Logging Configuration Tool” under your FX5U project.

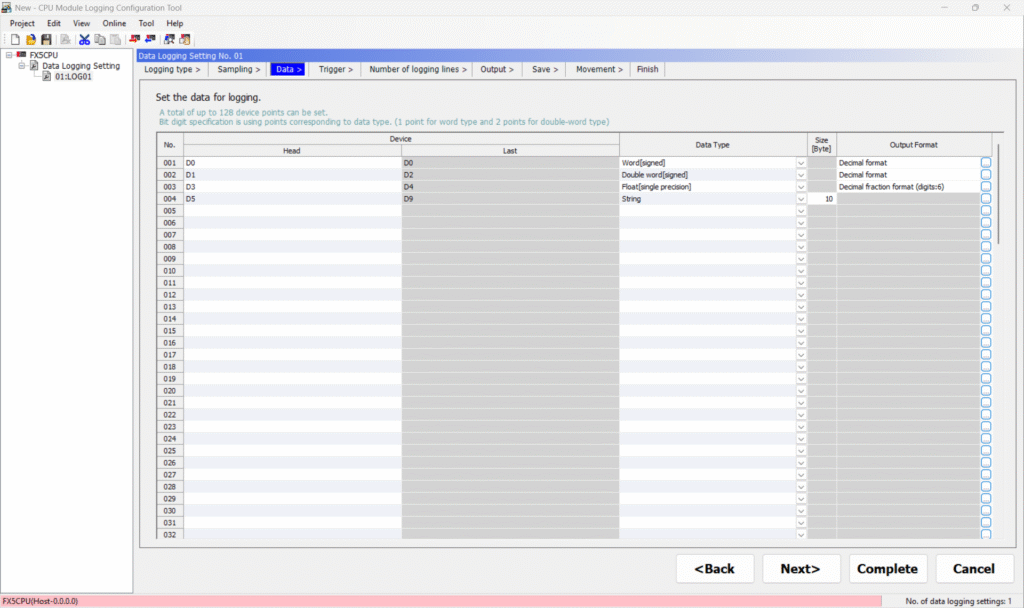

- Select which device memory areas (e.g., D0, M1) you want to log.

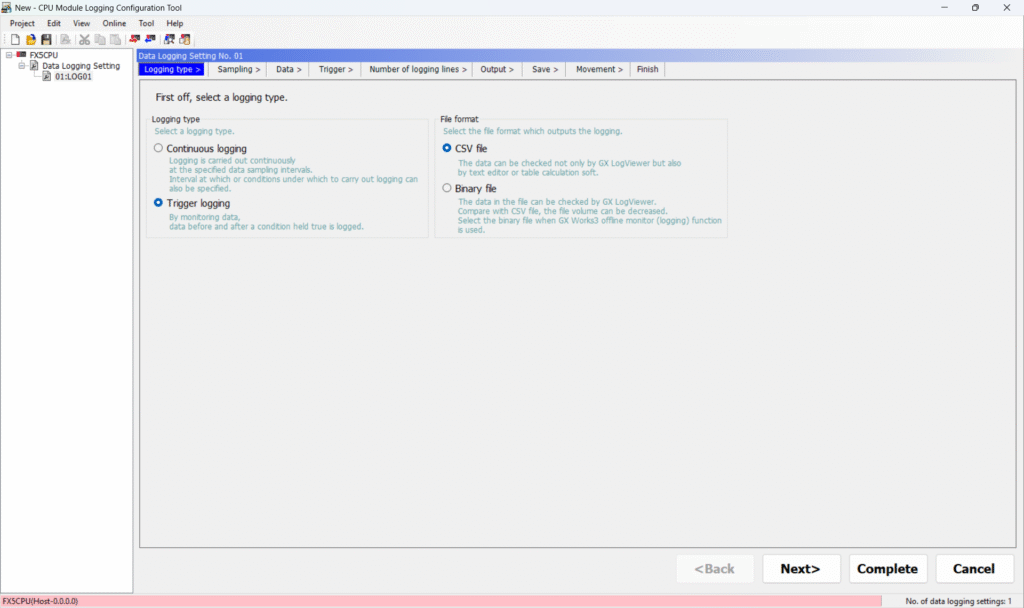

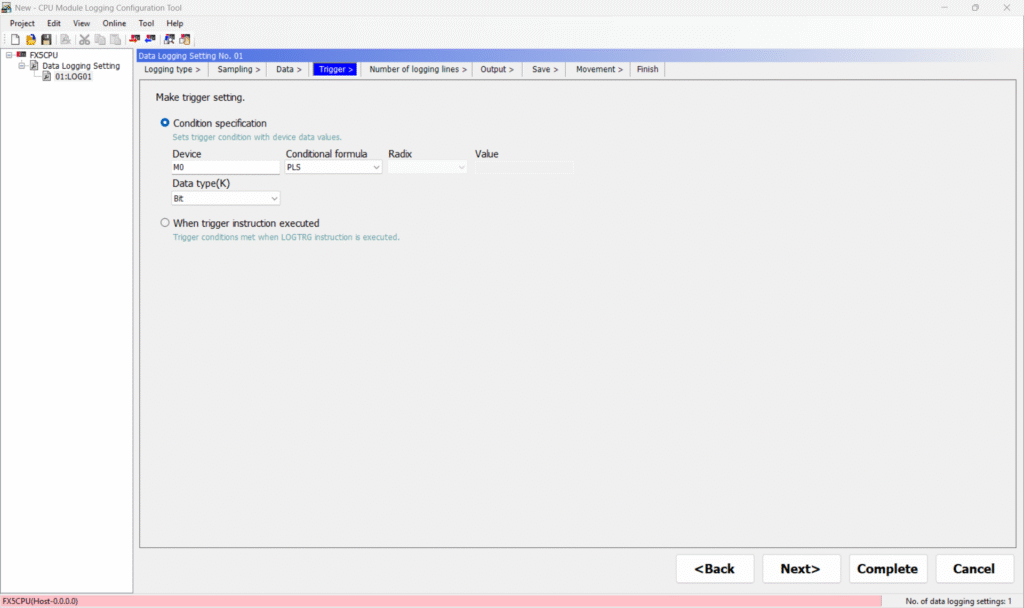

- Choose between continuous or trigger-based logging.

Step 3: Define Parameters

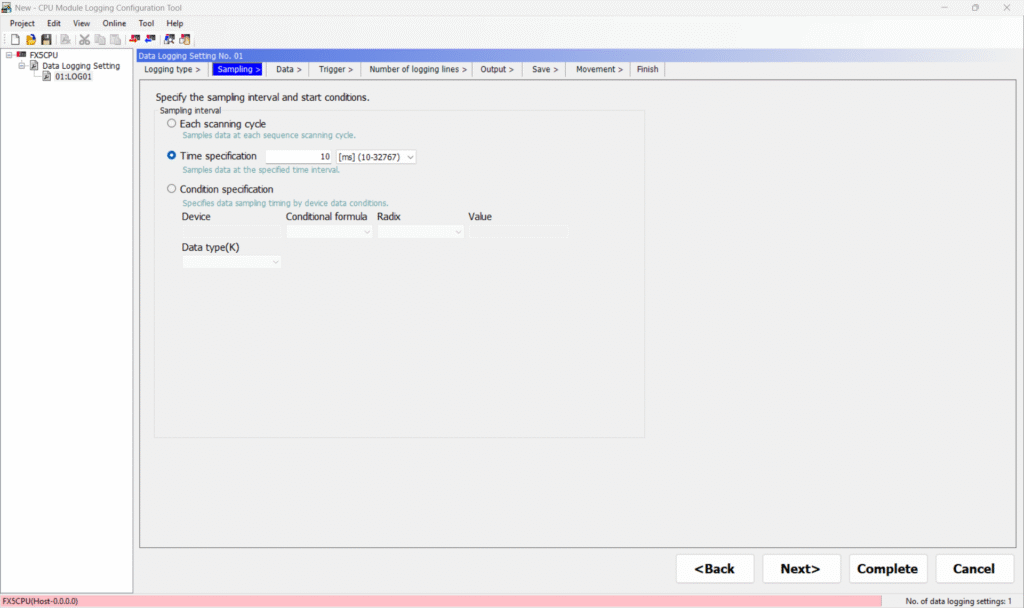

- Set your logging interval (e.g., every 100 ms).

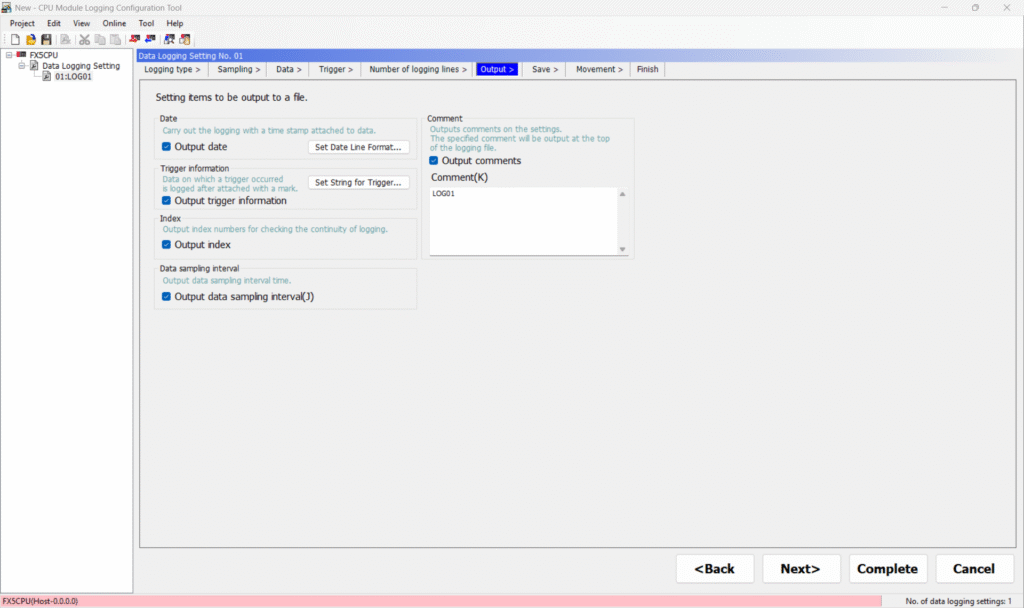

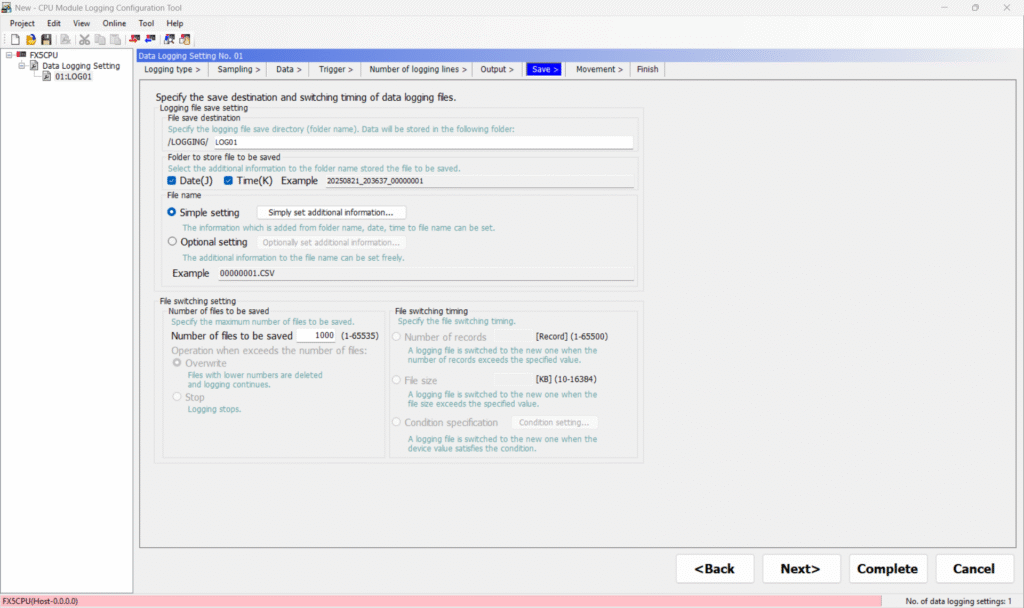

- Define file names, logging duration, and maximum file size.

- Choose between CSV (easy to open in Excel) or binary (more compact).

- Also you can refer 🔗 Official Resource: Mitsubishi Electric – MELSEC iQ-F Series

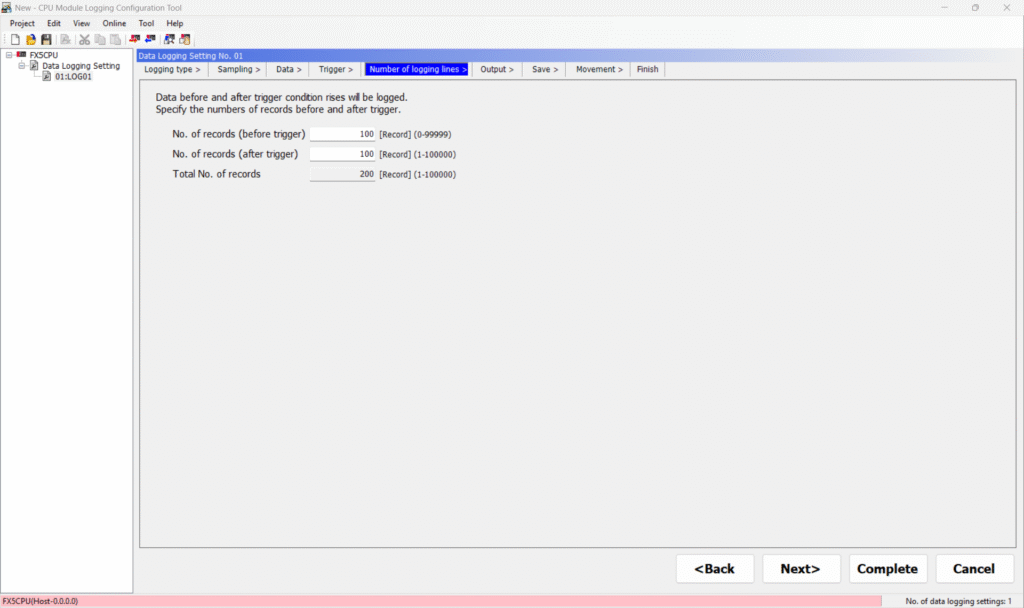

You can also log event-based data — for example, by setting a trigger such as M0, as shown in the image below. The system will record a defined number of data points before and after the trigger event, based on the sampling time configured earlier.

This method is especially useful when you need to investigate the cause or status of a specific device condition. By capturing data around the exact moment an event occurs, you gain clearer insights into what led up to it — and what happened immediately after. Refer below images for the same

Step 4: Enable Auto Logging

- Enable “Automatic Logging Start” so the FX5U begins logging automatically on power-up or SD card insertion.

Step 5: Deploy and Monitor

- Transfer your program and logging settings to the PLC.

- Insert the SD card and power on the system.

- The system will start writing data files according to your setup.

How is the Data Stored?

The FX5U saves logs as individual files with custom file names. You can configure it to:

- Overwrite old files (for continuous long-term logging)

- Stop logging once storage is full (ideal for audits or critical data)

File examples:

LOG_001.CSV

LOG_002.CSV

...

Each row contains timestamps and the values of the devices you’ve selected — perfect for diagnostics, traceability, or analysis.

You may also like Save and Load Programs Using an SD Card on Mitsubishi FX5U PLC

Real-World Applications

Logging to SD card is used in:

- Event Log for machine diagnostics

- Production line monitoring

- Energy consumption tracking

- Machine fault analysis

- Predictive maintenance

Using event triggers like a fault bit (e.g., M0), you can capture the exact device values just before and after a machine fault occurs.

Best Practices

| Tip | Why it Matters |

|---|---|

| ✅ Use high-quality SD cards | Reduces risk of data corruption. |

| ✅ Limit logging frequency | Prevents performance bottlenecks on the PLC. |

| ✅ Back up log files regularly | Avoids data loss if the card fails. |

| ✅ Use trigger logging for events | Saves memory and focuses on important data. |

🔗 Accessing Logged Data from the FX5U via FTP

Once your FX5U PLC has recorded data onto the SD card, you don’t need to physically remove the card to view the information. Instead, you can transfer the log files directly to your PC using FTP (File Transfer Protocol).

To do this, simply enable the FTP server function on the FX5U and connect to it using any standard FTP client software on your computer. This allows you to browse the SD card’s contents and download log files remotely.

Since the files are typically saved in CSV format, they can be quickly opened in spreadsheet applications like Excel for review, analysis, or troubleshooting — making it easy to track trends or investigate specific events captured during runtime.

Mitsubishi PLC FX5U Logging Configuration File

Found this guide useful? We’re always updating our content — don’t forget to revisit for new insights and tools.